The Evolution of HD Pipe Camera Technology

From analog to digital: The shift in video pipe inspection camera technology

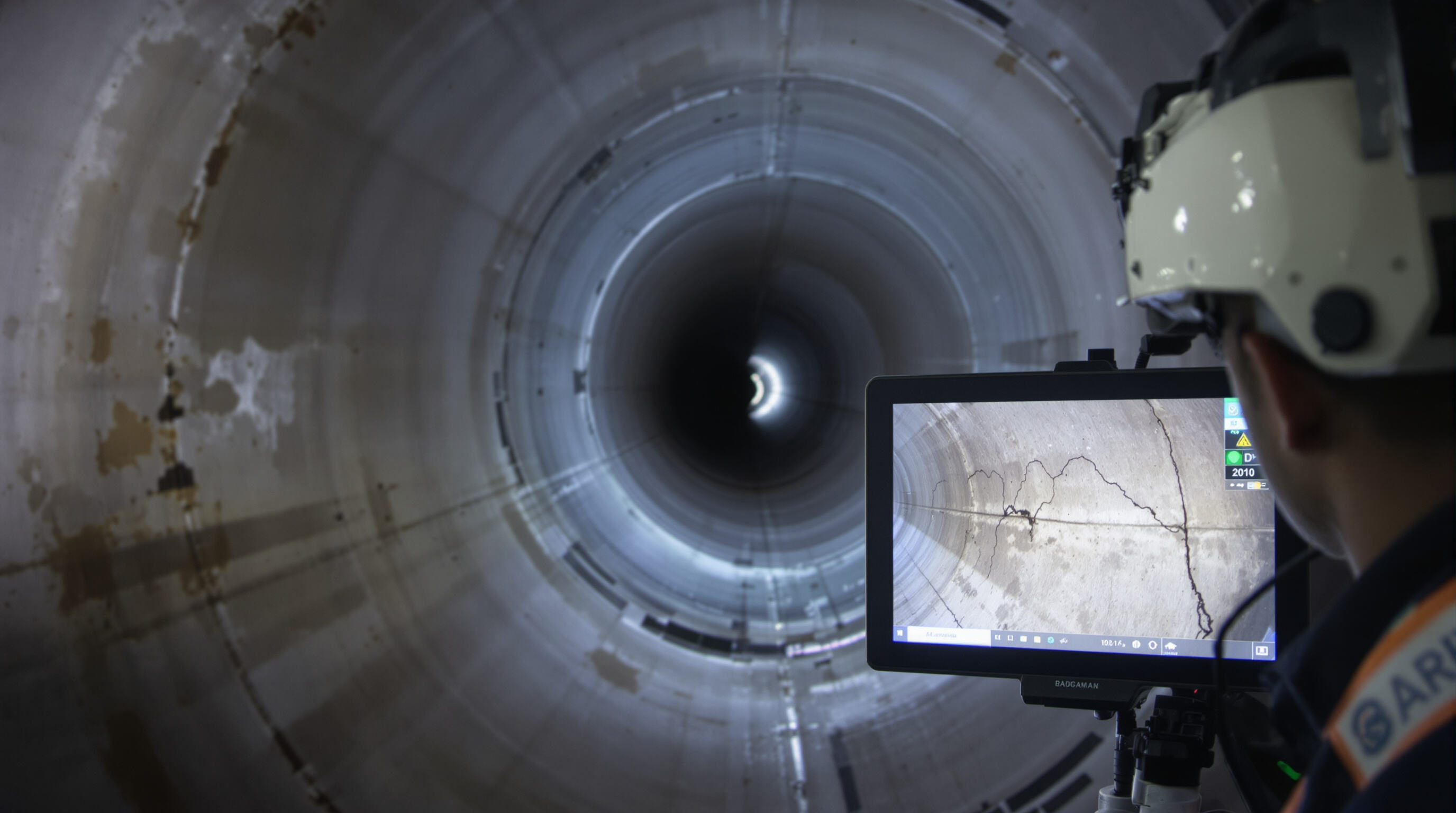

Switching from old school analog to modern digital tech really changed how we inspect pipes these days. Back in the day, those early cameras gave us nothing but fuzzy 480p images and hardly any way to save what we saw, so spotting issues was basically guesswork. Today's digital systems? They shoot crisp 1080p video with zoom that goes all the way up to 20 times, letting technicians see tiny cracks and roots creeping into pipes that would have gone unnoticed before. No more dragging around heavy VHS machines either. Now field workers can look at problems right away on their handheld screens or even stream findings directly to office computers via the cloud, which saves tons of time and money in the long run.

Advancements in HD-over-coax and its impact on image transmission

The introduction of HD-over-coax tech changed how old inspection systems worked because it allowed sending 720p or even 1080p video down those same coax cables that were already installed. What this meant for companies was they didn't have to throw away their existing wiring investments, which saved money. The picture quality went way up too, about four times better than what came before with those standard CVBS signals. Techs could see much clearer details on pipe walls without having to rip out all those expensive cable reels. Still there was a catch though. Older copper systems just couldn't handle the extra bandwidth needed for true full HD resolution, so performance stayed somewhat limited in these setups.

The role of 4K and HD imaging standards in sewer inspection camera advancements

The move toward SMPTE 4K and H.265 compression standards has really helped close some major holes in how we assess sewers these days. According to a recent 2023 study on wastewater infrastructure, those fancy 4K cameras can spot tiny 0.2mm cracks that completely slip past older 1080p systems. And let's face it, catching those little fractures before they turn into big problems saves municipalities tons of money down the road. What's more, these new standards work wonders in dim lighting conditions thanks to better CMOS sensor tech. Even in pipes as small as six inches across, technicians can now see what needs fixing when there's barely enough light to read by - around 8 lux is all that's needed according to specs.

Limitations of HD-over-coax: Latency, signal degradation, and color distortion

While cost-effective, HD-over-coax systems exhibit three key constraints in long-distance inspections:

- Latency: 200ms delay at 300ft distances hampers real-time defect tagging

- Signal Loss: 15% brightness degradation per 100ft in corroded conduits

- Color Shift: Improper impedance matching distorts rust/corrosion hues

These limitations drive adoption of HD-over-fiber systems for critical infrastructure inspections beyond 500ft ranges.

Image Resolution and Defect Detection Accuracy in HD Pipe Cameras

Understanding Camera Resolution and Image Clarity in Pipe Interior Imaging

High definition pipe inspection cameras now come equipped with cutting edge sensor tech that can capture images inside pipes at resolutions reaching 4K quality (those are 3840 by 2160 pixels for anyone counting). The increased number of pixels makes it possible for inspectors to spot tiny cracks just half a millimeter wide plus catch those hard to see signs of corrosion that regular definition systems simply miss. Many newer models feature progressive scan sensors combined with 12 bit color depth which means they can display around 4,096 different shades for each color. This level of detail helps technicians tell apart various issues like mineral buildup from tree roots growing into pipes or actual structural problems in the system.

Comparative Analysis of HD vs. Standard Definition in Defect Detection Accuracy

- HD systems (1920x1080 resolution) detect 98% of cracks ¥1 mm vs. 56% for SD (720x480)

- SD cameras miss 40% of early-stage pitting corrosion in cast iron pipes

- HD imaging reduces false positives by 62% in joint offset assessments

The NASSCO 2022 Infrastructure Report confirmed HD systems improved crack detection accuracy by 78% compared to analog predecessors through controlled field trials across 12 U.S. municipalities.

Importance of Clear, Uncompressed Video for Accurate Pipe Defect Detection

While HD-over-coax transmits up to 500m, its 4:2:0 chroma subsampling degrades color accuracy critical for distinguishing between clay pipe stains and active leaks. Uncompressed video pipelines using H.265 encoding preserve 4:4:4 color sampling at 60 fps, maintaining detail fidelity for:

- Precise crack width measurements (±0.1 mm)

- Accurate flow rate calculations via debris movement tracking

- Reliable AI-assisted defect classification (95% model confidence vs. 82% with compression)

Municipal operators report 33% fewer service callbacks when using lossless HD video transmission paired with 10x optical zoom capabilities.

Key Camera Design Features That Enhance HD Imaging Performance

Lens Technology and Zoom Capabilities in HD Pipe Cameras

Today's high definition pipe inspection cameras typically feature multi element glass lenses with fairly wide apertures ranging from f/1.8 to around f/2.4. These lenses help capture those sharp 4K images even when working inside tight spaces within pipes. The zoom capabilities are pretty impressive too, offering between 8 and 12 times optical magnification. This level of detail allows technicians to spot really tiny cracks that might be less than 2 millimeters across while still maintaining good image quality. Some newer models incorporate aspherical lens technology which cuts down on barrel distortion problems by about 37 percent when compared to older spherical lens designs. This makes a real difference for accurately measuring defect sizes during inspections.

Lighting and Visibility Enhancements: LEDs and Low-Light Performance

LED arrays designed for dual purposes usually produce between 20 to 50 lumens per square foot and tackle those tricky problems we face daily when inspecting pipes. They need to light up all sorts of uneven surfaces inside pipes and still get through murky fluids that make visibility almost impossible. The smart lighting systems these days can actually change their brightness depending on how much dirt is floating around and how cloudy the water gets, which helps keep colors looking right even when things are tough to see. Some newer models mix together infrared sensors at 850 nanometers with regular LED lights so they work better in really dark conditions down to half a lux. This combination maintains pretty good picture quality despite the challenging environment.

Integration of Panoramic and Laser Imaging in Pipe Inspection

Modern 360 degree panoramic camera heads can stitch images together with less than 1% error thanks to their six axis gyro stabilization tech. This creates pretty seamless maps of pipe walls covering around 100 feet in a single scan. Pairing them with those Class 1 laser profilers operating at 635 nanometer wavelengths makes all the difference. The combination produces super detailed 3D models right down to the millimeter level for things like corrosion pits and built up sediment. Real world testing has shown this setup cuts inspection time dramatically, about two thirds faster than regular old CCTV methods. And what's even better? The measurements are three times more accurate when it comes to spotting defects. That kind of precision is changing how inspections get done across the industry.

Real-World Performance Metrics of HD Pipe Cameras

Evaluating Frame Rate, Latency, and Color Fidelity in HD Pipe Camera Technology

The latest HD pipe inspection cameras now hit around 30 frames per second, which allows technicians to see what's going on inside pipes almost instantly. Field testing shows response times stay below 150 milliseconds most of the time. Better models keep about 95% color fidelity even when light levels drop, something plumbers really need for spotting early signs of corrosion or those pesky biofilms forming on pipe walls. Worth noting is how signal compression affects coaxial systems too. Some setups lose nearly 30% of their contrast when compressed, making it harder to spot small defects. That's why many professionals still prefer working with uncompressed video formats for detailed inspections where nothing gets missed.

Case Study: Municipal Sewer Inspection Using HD Cameras for Clear Pipe Interior Imaging

One Midwestern city saw a dramatic drop in overlooked problems when they switched out their old equipment for high definition pipe cameras capable of 4K resolution. City workers were able to spot those tiny cracks less than a millimeter wide in about eight out of ten clay pipes they checked something that just wasn't possible with the older analog systems. According to the latest Municipal Infrastructure Report from 2024, these kinds of upgrades have led to roughly a 22 percent reduction in emergency repair calls each year across fourteen different cities that made the switch. The savings add up fast when municipalities can catch issues before they become major headaches.

Trend: Rising Adoption of HD-over-Fiber for Superior Image Quality in Long-Distance Inspections

Fiber-optic transmission now supports 4K video transmission up to 1,000 meters without signal repeaters, compared to 300-meter limits in HD-over-coax systems. This technology eliminates color banding artifacts common in coaxial setups, with 98% of surveyed contractors reporting improved defect classification accuracy in pipe wall assessments beyond 500 feet.

Challenges and Future Considerations in HD Video Pipe Inspection

Signal degradation in long-distance HD video transmission

HD pipe cameras simply cannot maintain good video quality when inspecting long stretches of piping. The HD signal tends to weaken quite a bit as it travels through coaxial cables. About 15% signal loss happens every 300 meters or so, and things get really bad after around 500 meters where colors start shifting and images become all blocky. Some companies have switched to fiber optic solutions which cut down on signal loss to under 2% for similar lengths, though these need careful setup and maintenance out in the field. Then there are other problems too. Power lines running parallel to inspection routes create electromagnetic interference that messes with transmissions, making life difficult for technicians working in city areas where utilities run alongside roads and buildings.

Balancing bandwidth needs with real-time inspection requirements

When dealing with raw 4K video that eats up around 25 gigabits per second, there's a serious problem matching those bandwidth needs with what's possible for real time processing during pipe inspections. Field work we've seen recently indicates that anything over 150 milliseconds of delay makes it really hard for inspectors to steer their equipment properly when they need to react fast. The newer H.265 compression tech cuts down on bandwidth consumption roughly half compared to older H.264 standards without messing up our ability to spot defects, though it does add somewhere between 80 and 100 milliseconds extra wait time just for encoding. Some new systems boosted by 5G technology are showing real potential though. These setups managed to stream full 4K footage at only 45 megabits per second with just 65 milliseconds lag in those recent tests inside city sewer systems where everything was carefully controlled.

As HD pipe camera technology evolves, addressing these transmission limitations while preserving image fidelity remains paramount for reliable underground infrastructure assessments.

FAQs on HD Pipe Camera Technology

What are the advantages of HD pipe cameras over analog systems?

HD pipe cameras provide superior image quality compared to analog systems, allowing for clearer detection of pipe defects, such as tiny cracks and corrosion. They also offer real-time streaming, reducing time spent on site inspections.

Can HD-over-coax systems be upgraded to HD-over-fiber?

Yes, companies can upgrade HD-over-coax systems to HD-over-fiber for better transmission quality and longer distance coverage. This improvement can reduce signal degradation and improve defect detection accuracy.

How does 4K resolution impact sewer inspections?

4K resolution greatly enhances sewer inspections by allowing technicians to detect smaller defects that older systems might miss, improving maintenance efficiency and potentially preventing costly repairs.

What are common issues with HD-over-coax transmission?

HD-over-coax transmission can suffer from latency, signal degradation, and color distortion over long distances. Fiber-optic systems can help address these issues for superior image quality.

Table of Contents

-

The Evolution of HD Pipe Camera Technology

- From analog to digital: The shift in video pipe inspection camera technology

- Advancements in HD-over-coax and its impact on image transmission

- The role of 4K and HD imaging standards in sewer inspection camera advancements

- Limitations of HD-over-coax: Latency, signal degradation, and color distortion

- Image Resolution and Defect Detection Accuracy in HD Pipe Cameras

- Key Camera Design Features That Enhance HD Imaging Performance

- Real-World Performance Metrics of HD Pipe Cameras

- Challenges and Future Considerations in HD Video Pipe Inspection

- FAQs on HD Pipe Camera Technology