Traditional Pipeline Inspection Challenges

Labor-Intensive Manual Inspection Methods

Most pipeline assessments still rely on old school manual inspections, which means bringing in skilled workers who inevitably make mistakes sometimes. Inspectors either have to crawl inside pipes themselves or drag around simple equipment to spot problems. Either way, it takes forever and gives mixed results at best. Industry data shows something shocking too – almost half the money spent on these projects goes straight into paying people wages because they need experts working long hours. And let's not forget about safety issues. Workers get stuck in tight spots where air quality is terrible, and there's always that chance of coming into contact with dangerous chemicals. All these problems point to one thing clear as day: we really need better ways to check our pipelines without putting lives at risk or burning through budgets.

Time-Consuming Diagnostic Approaches

Old school diagnostic approaches really drag out the inspection process, which affects when projects get done and how happy clients are with the results. Most traditional methods still depend on ancient gear and procedures that just take forever to set up and run, causing all sorts of holdups. Studies show manual checks often last way longer compared to newer options like those fancy sewer cameras we've been seeing lately. Sometimes things get stuck for weeks before anyone even gets a look at what's going on down there. When diagnostics take so long, it means higher bills for pipe maintenance and real headaches with service disruptions because problems either go unnoticed or get fixed improperly. Switching over to tech-based inspections helps cut down on wait times and works better overall. Companies that made the jump report getting their assessments done in days instead of weeks, though there are still some holdouts clinging to old ways despite the clear benefits.

How Pipeline Endoscopes Revolutionize Maintenance

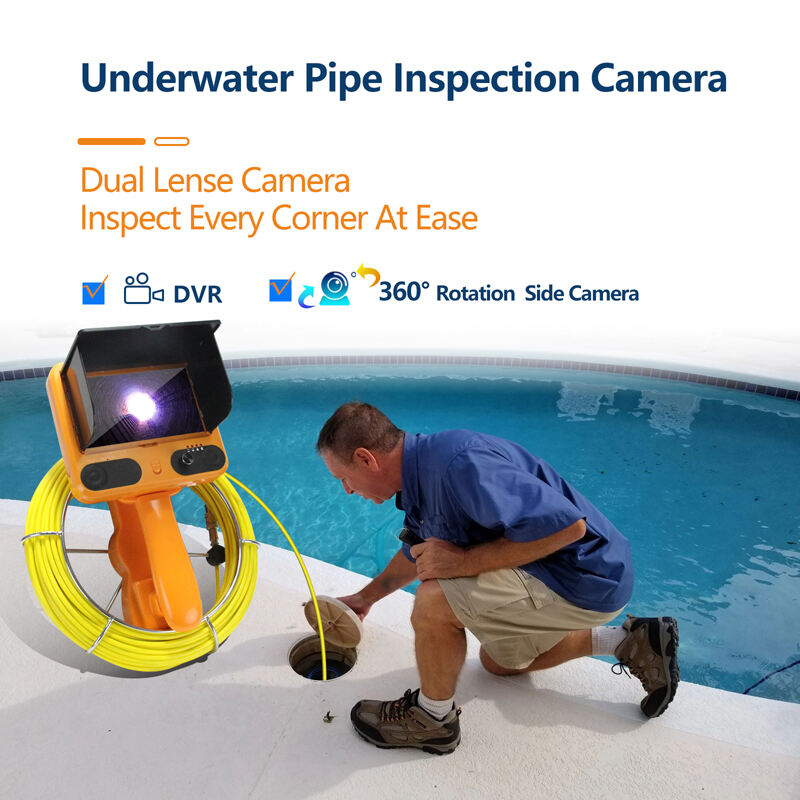

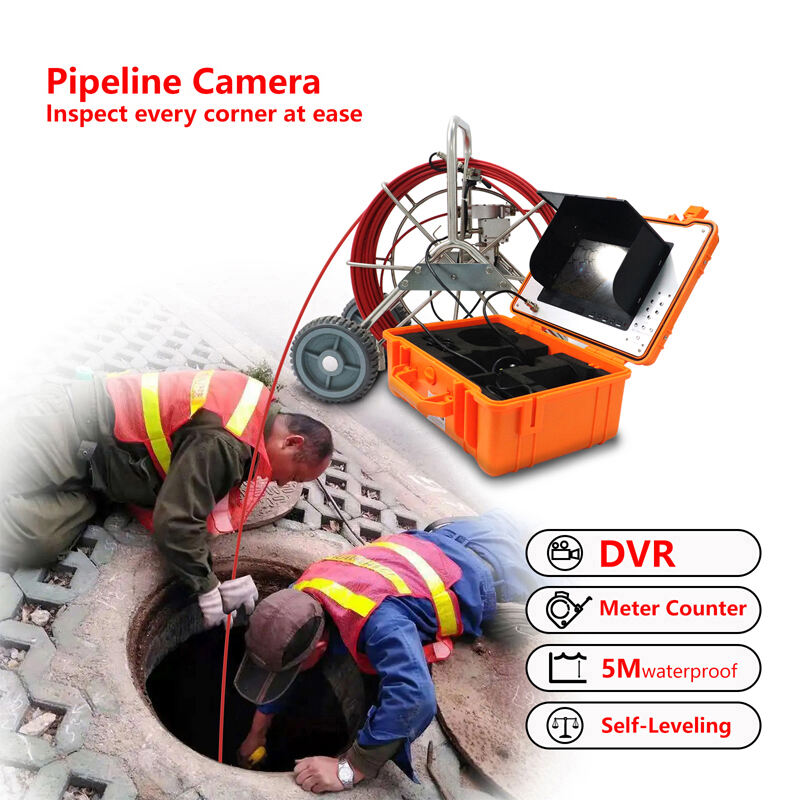

Core Technology Explained

Pipeline endoscopes are changing how we maintain pipelines because they bring some pretty impressive tech and smart design to the table. Most models come with those high res cameras and bendy bodies that let workers see exactly what's going on inside pipes without tearing everything apart. What really stands out is how well they handle tricky pipe layouts where traditional methods just fall short. When paired with today's data gathering systems, these scopes become even better at their job. Operators get live video feeds and all sorts of diagnostic info right there on site, which cuts down on guesswork when making repair decisions. Industry pros consistently point out that using these tools boosts both speed and accuracy during inspections, so fewer issues slip through the cracks. Research backs this up too, showing that inspection teams find about 30% more problems when working with endoscopes compared to older techniques.

Versatility in Sewer Systems

Pipeline endoscopes do much more than just check pipes; they're absolutely essential for keeping sewer systems running properly. These little machines can handle all sorts of tough environments from wet mud to tight corners, making inspections far more reliable than old methods. Real world tests show that using sewer cameras actually boosts successful diagnoses by around 40% in many cases, which explains why plumbers love them so much. What really matters though is how they cut down on dangers compared to manual checks where workers might get hurt crawling through dark, dirty tunnels. As more people start talking about plumbing cameras or drain cameras instead of just endoscopes, it shows we're moving toward smarter ways of doing things. The industry has definitely evolved beyond basic flashlight inspections into something safer and way more effective overall.

Labor Cost Reduction Strategies

Eliminating Excavation Expenses

Pipeline endoscopes give us a way to check pipes without all the digging headaches that usually come with it. Most old school inspection work means getting out the shovels and excavators just to find what's wrong underground, and let's face it, nobody wants their yard torn up for days on end. When companies use those tiny camera systems instead, they get to see everything inside the pipe while keeping the ground intact. One water utility in Texas told me they saved around 70% on digging costs after making the switch last year. And considering how much money gets spent on excavation alone in most inspection projects, those kinds of savings really add up. Plus there's another bonus nobody talks about much these days the instant feedback from live video feeds means problems get fixed faster before small issues turn into big repair bills down the road.

Reducing Workforce Requirements

Pipeline endoscopes really change how many workers are needed and cut down on labor expenses. Instead of needing big crews for inspections, small teams can now get the job done just fine. Take a look at modern sewer cameras these days – trained techs can read what they see and understand problems way faster than old school methods where people had to dig around and guess what was wrong. Sure there's some learning curve involved when getting familiar with these new tools, but most companies find it pays off pretty quick. According to industry reports, businesses that switch to endoscope inspections typically save around 30% on their labor bills over time. Less money spent on wages means more room for growth elsewhere, plus workers can inspect several sites in one day rather than spending hours at each location.

Time-Saving Benefits of Visual Inspections

Rapid Detection & Diagnosis

Pipeline endoscopes, including those handy sewer cameras we all know, make spotting problems in pipes much faster than traditional methods. These inspection tools let technicians see right into the pipe walls and catch typical issues like clogs from debris, hairline fractures, or roots growing through joints. Getting early warnings means plumbers can fix things before they become major headaches. Industry reports show that businesses that invest in visual inspection tech typically find problems weeks earlier than those relying on old school methods, which cuts down on costly repair delays. A local utility company saw their response time drop by almost 40% after adopting camera inspections, so it's not just theory anymore but actual practice saving money and preventing bigger disasters down the line.

Swift Decision-Making Capabilities

When pipeline endoscopes start sending real time video feeds during inspections, it completely changes how decisions get made on site. The sewer inspection cameras basically beam live footage straight to where the operators are working, so they can make calls right there instead of waiting for reports later. We've seen this work wonders across different jobs recently. Take for instance when crews spotted cracks in pipes almost instantly through these cameras. They could fix them before anything worse happened, which saved days off schedule and kept everyone following the rules about safety standards. Getting information fast means problems don't linger around causing bigger headaches down the road. Most plumbers will tell you that catching issues early makes all the difference between a quick repair job and having to shut things down entirely for weeks.

ROI Analysis: Cost vs Savings

Immediate Financial Benefits

Putting money into pipeline endoscopes such as sewer cameras often pays off right away in terms of saving cash. When companies switch to looking at pipes visually instead of other methods, they cut down both how much work needs doing and how long inspections take. Take it from plumbers who've actually done this: many report seeing their day-to-day expenses drop pretty quickly once they stopped relying on old school inspection approaches and started using those little camera snakes instead. The numbers tell the story too these tools give back what was invested pretty fast. Less time spent onsite means workers aren't hanging around waiting for results, which cuts labor bills and keeps clients happy since their normal routines aren't messed with so much. All told, getting good visuals inside pipes makes sense financially speaking, especially when today's businesses are always hunting for ways to keep costs under control without sacrificing quality service.

Long-Term Operational Savings

Sewer cameras offer more than just quick cash savings. They actually help keep things running smoothly over time by making maintenance work smarter and cutting down on those frustrating shutdowns when pipes go bad. When plumbers check sewers regularly with these high tech gadgets, it helps extend how long the whole system lasts because problems get spotted early before they turn into big messes. According to recent studies from several municipal water departments across the country, cities that adopted regular camera inspections saw around 30% less spending on emergency repairs after five years. For businesses looking at their bottom line, this means investing in good inspection equipment pays off handsomely in the long run. The money saved on unexpected breakdowns and costly fixes makes all the difference in keeping operational expenses under control without sacrificing service quality.