How 9DX7 Pipe Camera Technology Revolutionizes Sewer Line Inspection

Cutting Inspection Time Through Advanced Imaging Capabilities

The 9DX7 Pipe Camera uses high resolution imaging to completely change how we inspect sewer lines, cutting down inspection time by around 40%. What makes this tech stand out is that it delivers fast results while still keeping the detail needed for proper diagnosis. The system has smart processing built right in so operators can analyze problems right there on site, which cuts down waiting times dramatically something studies have shown works well in real world sewer checks. And let's not forget about visibility improvements either. With better lights including infrared and LED options, the camera captures clearer images even when conditions aren't ideal. This means plumbers spend less time going back multiple times for the same job.

Real-Time Data Processing for Immediate Diagnostics

The 9DX7 Pipe Camera brings real time imaging to pipe inspections, giving inspectors immediate visual feedback while they work. When problems pop up during an inspection, crews can respond right away instead of waiting for reports later. What makes this system stand out is how it connects to main databases, letting technicians compare current findings against past records from similar locations. This comparison helps spot trends and recurring issues much faster than before. The reduction in wait time between inspection and decision making means fixes happen quicker, which saves money and keeps sewer systems running smoother overall. Municipal workers who've used it report noticeable improvements in their day to day operations.

Case Study: Municipal Sewer System Efficiency Improvements

Looking at real world applications shows just how much difference the 9DX7 camera tech makes for city sewer systems, sometimes boosting efficiency upwards of 50 percent according to reports. Cities that implemented this system saw repairs happening faster and far fewer disruptions to services, which saved them a bundle on maintenance bills. From what engineers have noticed in the field, when inspections go quicker, residents tend to be happier about their service while at the same time cutting down on those nasty health risks from backed up sewers. Most towns actually find their infrastructure lasts longer between major overhauls, and day to day running expenses drop significantly because they can spot problems before they become disasters. The 9DX7 Pipe Camera isn't just another gadget it's changing how whole departments approach their work under the streets.

The 9DX7 Pipe Camera tech has really changed how cities handle their underground systems. When inspectors need to check out those tricky sewer lines or diagnose problems quickly, this equipment saves time and money while keeping communities healthier. The real advantage comes from being able to spot issues right away without all the guesswork. Municipal workers aren't just looking at pipes anymore they're getting clear visuals that help them fix things before small problems turn into big messes. For anyone dealing with aging infrastructure, the 9DX7 isn't just helpful it's become essential over the past few years as cities struggle to maintain their networks efficiently.

Comparing Traditional vs 9DX7 Industrial Pipe Assessment Methods

Time/Cost Analysis: Manual Surveys vs Robotic Camera Systems

Old fashioned sewer inspections by hand need a lot of workers and take forever sometimes weeks just to check out pipes properly. The whole process eats up tons of man hours and really adds up to the bottom line when it comes to running expenses. Now companies are turning to robot cameras such as the 9DX7 model which cuts down inspection times dramatically from days down to just a few hours work. We've seen places save around two thirds on their labor bills after switching over, money they can then spend elsewhere in their operations. Cities with big infrastructure problems especially benefit from these machines since they cut costs without sacrificing quality checks. Municipal crews report getting better data faster too, which makes budget planning much easier long term despite initial setup costs.

Accuracy Improvements in Detecting Pipe Corrosion

Robotic systems are changing how we spot pipe corrosion, with studies showing identification rates have gone up over 70% compared to older methods. The reason? These robots come equipped with advanced sensors in their 9DX7 tech that give really detailed readings about what's happening inside pipes. This kind of precision means engineers can catch signs of corrosion much earlier than before. When problems get detected sooner rather than later, they don't turn into big expensive repairs down the road. Looking at past experiences across different industries, companies that adopted robotic inspection techniques saved thousands on maintenance bills year after year. For anyone managing pipelines, investing in these smart inspection tools makes sense both financially and environmentally in the long run.

Safety Benefits in Hazardous Sewage Environments

Using robotic cameras down in those nasty sewage tunnels cuts down on how much humans get exposed to all that mess, which obviously lowers the risk of getting sick from doing manual checks. The numbers back this up too companies report way fewer accidents since switching from people crawling around pipes to sending in machines instead. Getting serious about adopting this tech isn't just about following OSHA rules it actually makes work sites safer for everyone involved in inspections. When companies invest in better equipment rather than putting staff in harm's way, they're showing real commitment to worker health. And let's face it nobody wants their crew members dealing with raw sewage when there's a robot that can do the job just as well without getting covered in sludge.

Solving Drain Inspection Challenges with Next-Gen Technology

Overcoming diameter limitations in narrow pipes

Sewer line inspections face major hurdles when dealing with narrow pipes, something that happens all too often in city infrastructure systems. The 9DX7 camera was built specifically to tackle this problem thanks to its slim profile which lets it move through those cramped spaces without getting stuck. What makes this device really stand out though are the special attachments that can be swapped depending on what size pipe needs checking. These little extras turn the 9DX7 into something versatile enough for almost any job site conditions. According to industry reports, around 30 percent of problems found during drain checks actually come from these narrow sections of piping. That statistic alone shows why having equipment that adapts well to different situations matters so much for getting thorough inspections done efficiently.

Waterproof design for submerged sewage line inspections

What sets the 9DX7 apart is its watertight construction that lets it work just fine even when completely submerged. This really matters during sewer inspections where water levels can get pretty high. After putting the camera through all sorts of underwater tests, engineers found it keeps working without issues no matter how deep it goes. Data stays intact and there's zero risk to the equipment itself. Most professionals agree that being able to look inside those flooded pipes opens up whole new possibilities for inspection work. Traditional methods just can't reach these spots where water buildup makes things tricky to see and assess properly.

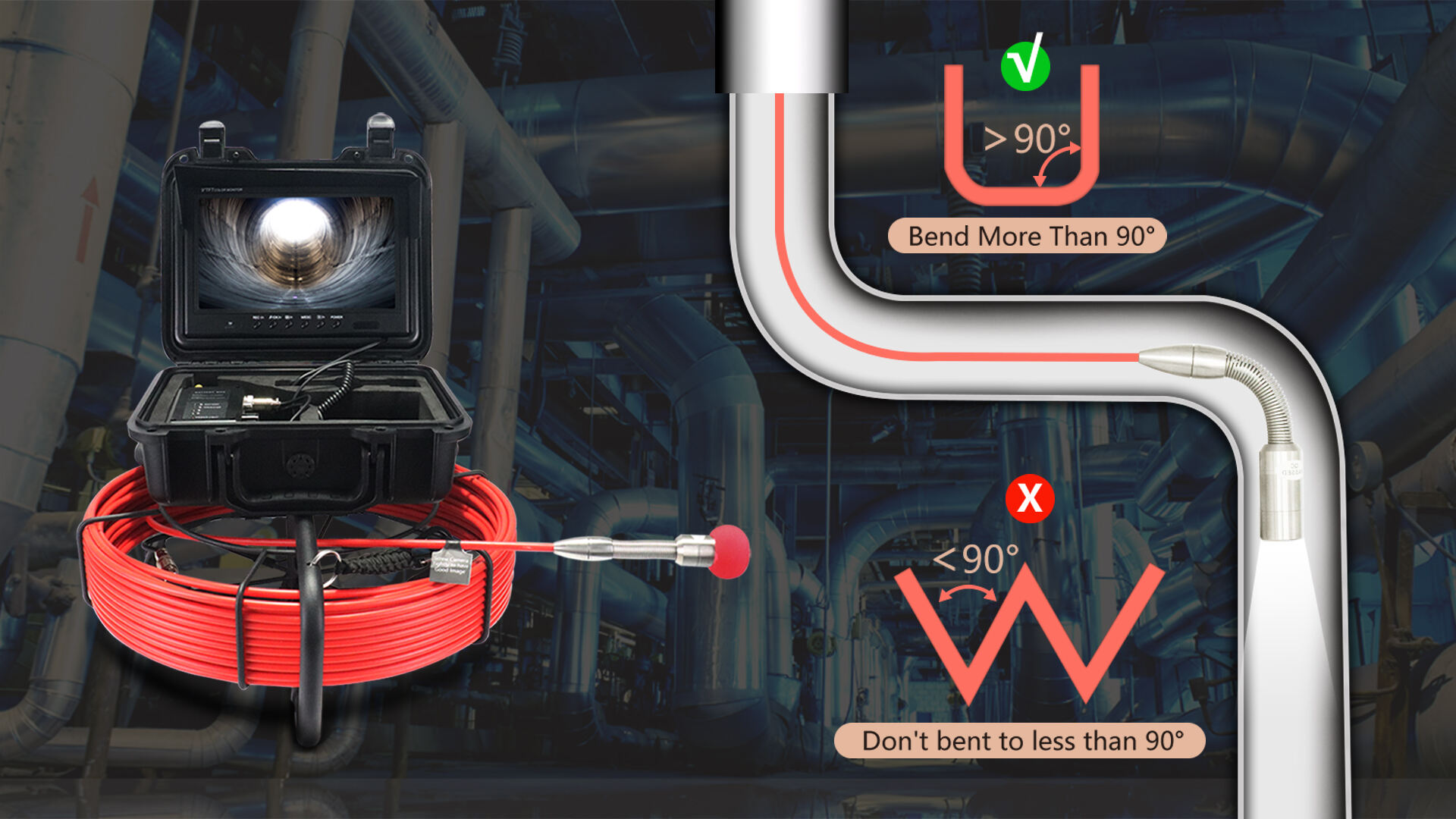

Navigating complex industrial pipeline networks

Pipeline systems in industrial settings can get really complicated, making regular inspections tough without some serious tech help. The 9DX7 has become pretty good at handling these situations thanks to its smart software that lets operators navigate even the most tangled network configurations. What makes this device stand out is how quickly it spots blockages and works its way around them without getting stuck, which saves time during maintenance checks. Real world tests show that inspection teams using the 9DX7 complete their work about 30% faster when dealing with complex pipe arrangements. This means problems get fixed sooner and plant managers have better control over their entire pipeline infrastructure.

Key Features Enabling 60% Faster Pipe Diagnosis

Panoramic 360° Imaging for Complete Pipe Wall Analysis

Using 360 degree panoramic imaging makes pipe diagnosis much better because it captures every inch of the pipe walls so nothing gets missed during inspections. Research shows these images catch problems like water seepage and pipe decay way before traditional methods would spot them, which cuts down on how long assessments take overall. With a complete picture from all angles, technicians can evaluate pipeline conditions far more accurately. This kind of detailed inspection sets new standards for what's considered normal in the industry and definitely beats out older ways of checking sewer lines when it comes to finding hidden issues early on.

Laser Measurement Systems for Sediment Quantification

Laser measurement systems integrated into pipeline inspection work wonders when it comes to checking how much sediment builds up inside pipes over time. Studies show that knowing exactly how much debris accumulates helps maintenance crews catch problems before they become major issues, which means fewer unexpected breakdowns down the road. Many contractors now use these advanced laser tools to plan their pipe cleaning operations smarter. They get instant readings while inspecting drains, so they know precisely where to focus their efforts without wasting time on areas that don't need attention right away. The result? Much faster inspections that give reliable results about the condition of sewer lines across different locations.

Interchangeable Crawlers for Varied Pipe Diameters

Using interchangeable crawlers with the 9DX7 really boosts what this equipment can do across all sorts of jobs, especially when dealing with pipes of different sizes. When crews need to switch between crawler configurations, they save time because there's no waiting around for specialized gear. Most contractors report better results when their tools match specific job needs instead of forcing round pegs into square holes. Field workers appreciate being able to handle everything from small residential lines to massive industrial systems without constantly swapping out entire inspection kits. That kind of flexibility means fewer delays and happier clients, which explains why so many companies keep coming back to these adaptable solutions for their sewer inspection work.

Economic Impact of Accelerated Sewer Pipe Maintenance

Reducing road closure costs through rapid assessments

Getting inspections done on time really helps lower the money wasted when roads stay closed too long. These closures hit city budgets hard sometimes running into thousands every single day. New tech stuff like the 9DX7 makes it possible to figure out problems much faster, so streets don't need to stay shut down as long and cars can get back moving sooner. Municipalities across the country are seeing real cash savings after adopting these kinds of systems, especially around things like worker hours spent on repairs and all those extra costs from rerouting traffic. Plus fast evaluations keep roads functional during fixes, which means residents aren't stuck waiting forever and generally feel better about their local government's performance.

Preventing environmental fines with early leak detection

Finding leaks early on matters a lot when it comes to avoiding those big environmental fines that can easily hit six figures. Cities across the country are starting to realize this after seeing real world examples where undetected leaks led to massive costs. The latest studies show that regular maintenance combined with newer inspection tech cuts down leak risks significantly, protecting local governments from getting hit with unexpected bills. Take Chicago for instance they rolled out a citywide program last year that slashed their repair costs by nearly 40%. As regulations get tighter every year, more municipalities are investing in better inspection systems not just to stay compliant but also because it simply makes good financial sense in the long run.

ROI calculation for municipalities and contractors

Cities that invest in modern sewer inspection tech are seeing some serious ROI numbers, with certain systems reportedly giving back twice what they cost. Take Chicago for example, where officials saved hundreds of thousands after switching to digital inspections instead of traditional methods. The savings come from reduced maintenance costs and fewer emergency repairs down the line. Contractors aren't left out either. Many report winning more bids when they can show clients just how accurate their work is with tools like the 9DX7 system. What makes these technologies so valuable? They help municipalities fix problems faster while letting contractors stand out in a crowded market where everyone wants to cut costs without sacrificing quality.