The Critical Role of HD Pipe Cameras in Modern Infrastructure Assessment

How HD Pipe Cameras Transform Pipeline Condition Evaluation

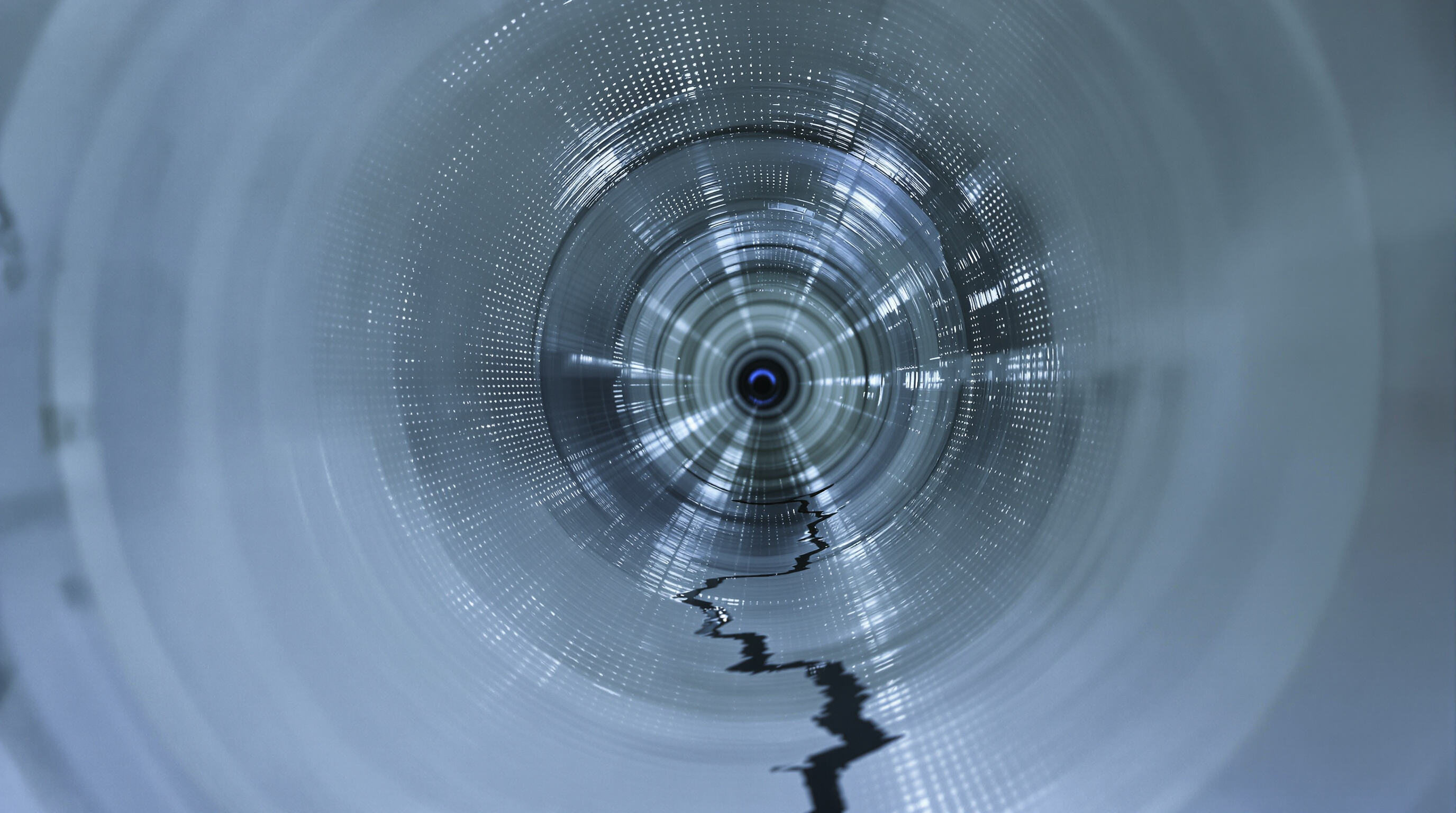

High definition pipe cameras are changing how we maintain underground infrastructure, moving away from old fashioned guesswork toward actual evidence based assessments. The technology works by sending HD cameras attached to flexible rods into pipes as narrow as 2 inches wide, which means no more digging up streets just to check what's going on below ground. Cities and water companies across the country are adopting these inspection methods to spot problems like cracks in pipe walls, accumulated debris, and tree roots breaking through with impressive accuracy rates around 98%, per the latest Water Infrastructure Report from 2024. What makes this approach so valuable is that it cuts down on repair bills by roughly half in many cases, all without tearing apart roads or damaging green spaces that took years to establish.

High-Resolution Imaging for Precise Detection of Cracks, Corrosion, and Blockages

HD pipe cameras today can record 1080p footage with impressive 30 times optical zoom capabilities. They spot flaws as tiny as half a millimeter wide, which is actually smaller than the tip of a regular pencil. Such detailed imaging helps plumbers tell apart surface stains from serious corrosion problems, something that matters a lot when deciding what needs fixing first in old water pipes. The image stabilization feature keeps things clear even when moving through rapidly flowing drains. Special lights with polarization settings make those barely visible cracks stand out in shadowy pipe joints where they would otherwise go unnoticed. According to research published last year, these high definition systems catch around forty percent more issues at an early stage compared to regular CCTV equipment. That means fewer surprises down the road and much less chance of major pipeline failures under pressure.

Real-Time Visual Data in Challenging Pipe Environments

These high definition pipe inspection cameras get the job done in places no person can reach. They send back live video from all sorts of tough spots like flooded storm drains, those nasty grease backups at restaurants, and even industrial pipes contaminated with chemicals. The cameras come in IP68 rated waterproof cases that can handle being submerged as deep as 30 meters underwater. And there are special heated lenses on them too, so they don't fog up when working in areas filled with steam. Most models have articulating heads that spin around completely 360 degrees, making it possible to check out those tricky side connections in sewer systems. Some units also feature different lighting options between regular LEDs and infrared lights depending on what kind of mess they're looking at whether it's murky wastewater or pipes full of oil. When things go wrong, these cameras overlay real time data showing exact GPS locations and pipe sizes right onto the video feed. This helps engineers make quick decisions when assessing emergencies without having to wait for later analysis.

Advancements in Image Resolution and Sensor Technology for HD Pipe Cameras

Understanding Resolution Metrics: Why HD Matters in Pipe Inspection

Modern HD pipe inspection cameras can now capture images at resolutions ranging from 1080p all the way up to impressive 4K quality. These devices are actually able to spot tiny cracks measuring just half a millimeter across. When manufacturers moved away from older 720p technology to these higher definition systems, they noticed something significant. Engineers could detect signs of corrosion and those little hairline fractures much earlier without having to dig up roads or disrupt neighborhoods. According to research published in 2023 about wastewater infrastructure, this upgrade in camera tech cut down on missed problems by around 72 percent when compared with what used to be standard equipment. And there's real money saved too – municipalities reported spending approximately eighteen thousand dollars less for each mile of pipeline they checked out with these new HD tools instead of relying on outdated models.

Comparing Standard vs. High-Definition Imaging in Field Applications

| Feature | Standard Imaging (720p) | HD Imaging (1080p+) |

|---|---|---|

| Minimum Crack Visible | 2.5 mm | 0.8 mm |

| Corrosion Recognition | Moderate surface pitting | Micro-pitting layers |

| Inspection Speed | 15 ft/min | 22 ft/min |

Field tests in municipal stormwater systems show HD cameras reduce inspection time by 31% while increasing diagnostic accuracy from 68% to 94%, according to NASSCO’s 2024 performance benchmarks.

How Modern Image Sensors Enhance Clarity and Detail Capture

The latest CMOS sensors equipped with back-side illumination (BSI) tech boost light sensitivity about four times better in those really murky drain situations where visibility is next to nothing. Some models now incorporate quantum dot layers that actually keep colors looking right even when submerged in cloudy water. This makes it possible to tell the difference between algae buildup and actual pipe damage something that was pretty much impossible before according to industry folks. Speaking of improvements, the 2024 Advanced Image Sensors Market Report points out this as one of the major breakthroughs lately. These sensors also come with built-in noise reduction features that cut down on all that pesky particle clutter. Most systems maintain around 90% image quality even when dealing with wastewater conditions where you can barely see your hand in front of your face sometimes less than 10 centimeters worth of visibility.

Lighting and Visibility Innovations in Waterproof HD Pipe Cameras

LED and Infrared Lighting Solutions for Low-Visibility Drain Inspections

HD pipe camera systems now come equipped with adaptive lighting featuring 24 LEDs across five different brightness settings. These lights can reach as high as 1,500 lux, which is basically like bringing daylight conditions into those pitch-black underwater environments where traditional methods fall short. For checking out sediment accumulation inside stormwater drains, infrared technology makes all the difference. It allows inspectors to look around without disturbing anything, so the delicate microbial communities stay intact. According to findings from the 2023 Water Infrastructure Report, when using infrared imaging after floods instead of just regular visible light, professionals saw a significant boost in their ability to assess damage accurately - nearly 38% better results overall. This kind of improvement means faster response times and smarter maintenance decisions for municipalities dealing with aging infrastructure.

Overcoming Challenges of Murky Water and Narrow Pipe Conditions

Waterproof HD cameras equipped with hybrid optical tech spot defects in murky water at rates around 80% better than regular models according to field tests. The combination of special anti-glare coatings on lenses plus real time contrast tweaks helps cut through all that cloudiness caused by floating particles in the water. When dealing with smaller pipes less than 2 inches across, there are now these tiny 9mm camera heads available that still deliver full 1080p clarity even when they have to turn sharp corners at 90 degrees. This solves one of those ongoing problems plumbers face during inspections of city sewers where space is tight and visibility is poor.

Design Features That Make HD Pipe Cameras Effective in Rugged Environments

Durable, Waterproof Construction for Harsh Inspection Conditions

High definition pipe inspection cameras come with tough housings rated IP68, constructed from durable aerospace quality polycarbonate combined with stainless steel components. These rugged devices can handle pressures up to 150 pounds per square inch and operate reliably in extreme temperatures ranging between minus 20 degrees Celsius and 60 degrees Celsius. They meet all necessary NASSCO guidelines required for inspecting underground utilities. The design includes dual O ring seals that keep out debris like silt, raw sewage, and other damaging fluids. This makes the equipment trustworthy when assessing stormwater systems after heavy flooding events, something municipal workers encounter regularly during rainy seasons.

Articulating Camera Heads and Flexible Push Rods for Maneuverability

These inspection cameras come with rotating heads that can turn all the way around and tilt up to 270 degrees either way, making them perfect for getting into those really tight corners and spots where regular rigid systems just won't go. They've got powerful motors inside that let the camera move smoothly around those sharp 90 degree turns in six inch diameter pipes. What makes these units stand out is their special Kevlar reinforced push rods covered in polyurethane, which gives them about 550 Newtons of pushing power without any risk of kinking. This means they can reliably work their way through stubborn root blockages and accumulated sediment that often clogs up old clay pipelines over time.

Integration with Smart Devices and Remote Monitoring Systems

Field technicians now send high quality 1080p video over Wi-Fi 6 connections to their tablets which run various cloud based inspection apps. This setup lets them work together instantly with engineers who aren't on site at all. When looking at pipes or infrastructure through these videos, teams can actually highlight issues like cracks forming or where joints aren't properly aligned while watching the footage in real time. All recorded material gets saved automatically with GPS data attached using the standard WGS84 coordinate system. What this means is we end up with complete records that meet regulatory requirements and can be easily searched later. These archives follow the ASTM F1216 guidelines specifically for planning repairs without digging up roads or sidewalks.

Reliable Recording and Documentation with HD Pipe Inspection Systems

Robust recording is essential for maintaining inspection integrity. HD pipe camera systems with dual storage—onboard SD cards and encrypted cloud backups—reduce data loss incidents by 54% compared to single-storage units, according to the Water Infrastructure Journal (2024). This hybrid approach ensures reliability in remote or connectivity-limited environments.

Onboard vs. Cloud-Based Video Storage: Ensuring Data Integrity

Onboard storage offers immediate access without relying on internet connectivity, ideal for rural or deep-utility inspections. Cloud-based systems support real-time collaboration and automated redundancy. Leading platforms apply military-grade encryption to both storage types, complying with ISO 27001 standards for secure utility asset documentation.

Timestamped Video Logs for Regulatory Compliance and Maintenance Reporting

When automated geotagging combines with timestamp overlays, it creates detailed records that satisfy most wastewater management rules across nearly all U.S. states except for a couple. For maintenance crews, having access to these rich video logs makes a real difference. According to recent data from the NASSCO PACP Report last year, teams can fix repeating problems almost 40% quicker when they look at how conditions have changed over time. The system also includes handy annotation features where inspectors can mark important spots right on the video itself. This means no more separate notes or guesswork about what needed attention where, making the whole process of documenting issues and deciding which repairs come first much smoother in practice.

Frequently Asked Questions

What is the advantage of using HD pipe cameras over traditional inspection methods?

HD pipe cameras provide high-resolution imaging that allows for precise detection of issues such as cracks, corrosion, and blockages without the need for digging up streets, significantly reducing repair costs and avoiding damage to established environments.

How do HD pipe cameras handle challenging pipe environments?

HD pipe cameras can operate in flooded storm drains and pipes contaminated with chemicals, featuring waterproof cases and heated lenses to avoid fogging. They provide real-time visual data and can be equipped with various lighting options and GPS data overlays for efficient emergency assessments.

What improvements have been made in HD pipe camera technology?

Recent advancements include higher resolution imaging, superior sensor technology for enhanced clarity and detail, adaptive lighting solutions, and durable camera construction for harsh environments. These innovations enable better detection of defects, faster inspection times, and increased diagnostic accuracy.

How do HD pipe cameras ensure data integrity and documentation?

HD pipe cameras use dual storage systems (onboard and cloud-based) with military-grade encryption to secure data and maintain inspection integrity, while timestamped video logs and automated geotagging facilitate regulatory compliance and efficient maintenance reporting.

Table of Contents

- The Critical Role of HD Pipe Cameras in Modern Infrastructure Assessment

- Advancements in Image Resolution and Sensor Technology for HD Pipe Cameras

- Lighting and Visibility Innovations in Waterproof HD Pipe Cameras

- Design Features That Make HD Pipe Cameras Effective in Rugged Environments

- Reliable Recording and Documentation with HD Pipe Inspection Systems

- Frequently Asked Questions