How Retractable Inspection Cameras Improve Industrial Diagnostics

Retractable inspection cameras revolutionize industrial diagnostics by enabling non-destructive testing in confined spaces, reducing operational downtime by up to 40% in pipeline systems (Ponemon 2023). These tools combine telescopic reach with high-definition imaging to identify defects in hard-to-access areas, from HVAC ducts to underwater infrastructure.

Principle: The Technology Behind Retractable Probe Mechanisms

What makes this technology stand out is actually the extendable shaft on the camera. It can stretch all the way to 15 meters long but still stays strong enough not to bend or break. There's also this special spring mechanism that lets operators point the camera almost anywhere they need to see inside pipes and around those tricky corners in reactor vessels. We've seen some pretty impressive results too. According to recent tests done in industrial settings, these new systems cut down inspection times by about two thirds when compared with old fashioned fixed length scopes used in power plant boilers.

Case Study: Detecting Corrosion in Petrochemical Plant Pipelines

A 2022 refinery audit in Texas demonstrated the cost-saving potential: technicians identified wall-thinning corrosion in 8" crude oil pipelines using a 10mm-diameter retractable camera, preventing a potential $740k shutdown (Ponemon 2023). The system's waterproof IP68-rated housing withstood 90°C temperatures and hydrocarbon exposure, validating its use in harsh chemical environments.

Trend: IoT Integration and Real-Time Remote Video Inspection

These days, modern equipment can send out 4K quality video footage straight to cloud storage through those industrial IoT standards such as OPC UA. According to actual field reports, maintenance crews who have access to these remote diagnostic features manage to fix issues with turbine blades around 30 percent quicker when they work alongside engineers located elsewhere. Still, nearly six out of ten facilities continue facing serious problems with too much data coming in at once. That's why there's growing interest in smart analysis software powered by artificial intelligence. The numbers speak for themselves from the latest Industrial IoT Index released in 2024.

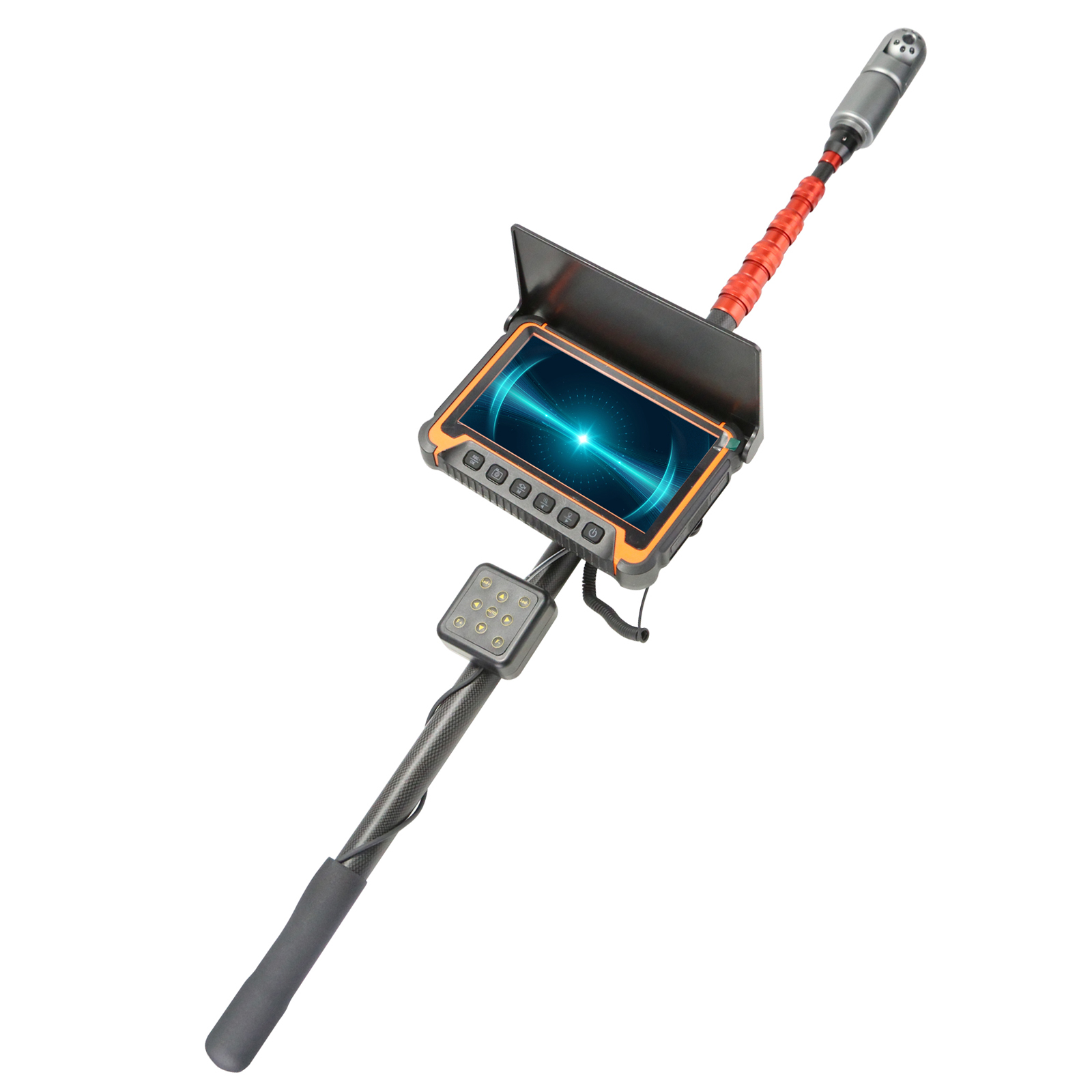

Core Mechanics of the Retractable Inspection Camera Structure

Today's retractable inspection cameras use specially designed telescoping systems that manage to be both portable and sturdy enough for real work. These cameras typically have a three-part folding design similar to those fancy trekking poles hikers use. When folded up, they can fit into something around 15 inches long but stretch out all the way to nearly 47 inches when needed for tight spaces. Most models come with two different locking systems these days. One lets inspectors get things set up quickly with a simple twist, while another provides extra stability when weight needs to be supported during inspections. Aluminum alloys make up most industrial grade units according to recent surveys from last year showing about 68% market share. This material works so well because it packs good strength without adding too much weight, sitting right around 2.8 grams per cubic centimeter.

Material Innovations: Waterproof and Chemical-Resistant Construction

Industrial-grade retractable poles now integrate marine-grade aluminum and carbon fiber composites to withstand harsh environments:

| Property | Aluminum Alloy | Carbon Fiber Composite |

|---|---|---|

| Corrosion resistance | 8/10 | 9/10 |

| Chemical resistance | 6/10 | 9/10 |

| Weight (per meter) | 420g | 290g |

New IP68-rated models combine hydrophobic polymer coatings with sealed cable routing, surviving 72-hour salt spray tests (ASTM B117 standard) without degradation. This aligns with findings from the 2023 Industrial Materials Report, showing a 40% increase in demand for chemical-resistant inspection tools in petrochemical sectors.

Stability and Adjustability in Extended Reach Applications

The design features a tapered wall that goes from 1.2mm at the base down to just 0.8mm at the tip, combined with strong threaded connections that resist twisting forces. This allows for extensions up to 10 meters long while keeping bending below 2 degrees even when subjected to lateral forces of around 15kg. For those tricky situations where pipes turn corners or meet at junctions in sewers, there are adjustable friction collars on site that let operators change angles in 15 degree steps. Some newer models being tested right now can actually rotate completely around in all directions at maximum length thanks to their modular segments. Wind farm technicians report cutting down inspection times by nearly 40% during recent blade inspections according to field reports from last year.

High-Resolution Imaging for Clear Visual Diagnostics in Tough Conditions

Advancements in Image Capture, Resolution, and Storage

The latest generation of retractable inspection cameras comes equipped with 4K resolution sensors combined with those fancy multi-frame super-resolution algorithms. This setup lets users zoom in digitally up to 12 times without losing clarity or getting those annoying pixelated images. Inspectors can spot really tiny hairline cracks measuring around 0.1 millimeters in width within rusted pipes or weld seams. For storing all this high quality footage, manufacturers have started using something called lossless HEIF compression which cuts down on file size by roughly 40 percent compared to traditional formats. What makes this so important is that even after compression, these videos still retain enough detail for thorough examination later on when analyzing problems found during inspections across various industrial settings.

LED Lighting and Focus Control for Optimal Clarity

The dual spectrum LED arrays range from 3000K warm white all the way up to 6500K daylight, and they come with adaptive brightness controls so things stay properly lit whether we're looking at totally dark sewer tunnels or super bright areas inside refineries where reflections can be blinding. These inspection tools also feature parfocal lenses that actually work pretty well for keeping everything sharp even as the camera moves along pipes and through tight spaces something most standard equipment just can't handle without constantly refocusing. And there's this real time HDR processing too which makes a huge difference when moving from really dark sections of piping to spots where fluids create those annoying reflective surfaces that mess up normal cameras so badly.

Balancing High Resolution with Data Management in Field Use

For industrial operations, getting the most out of workflows means combining 5MP cameras with those new Wi-Fi 6 field tablets. These setups can send those short 30 second inspection videos to the cloud in just 12 seconds flat. The latest edge computing gear actually does some processing on site first, spotting problems in the video feed before sending everything up. This cuts down bandwidth needs by around 70% when working in areas where cell service is spotty or non-existent. What we're seeing here is a smart mix of technologies that lets companies keep their high res imaging capabilities without slowing things down during long term diagnostics and maintenance checks across multiple locations.

Key Applications in Plumbing, Sewer Lines, and Confined Space Inspections

Overcoming Obstacles in Drain and Pipeline Inspections

Retractable inspection cameras are really good at spotting those everyday problems inside pipelines such as hair blockages, built-up grease, and roots growing through cracks. They can snake their way around tight corners down to about 45 degrees and work across different types of pipe material without issue. Take petrochemical pipelines for instance where corrosion is a big problem costing companies roughly seven hundred forty thousand dollars each year because of unexpected shutdowns. Early detection becomes possible thanks to tiny probes under five millimeters thick that bend all the way around. According to what we see from field reports, these camera systems cut down on inspection times by almost two thirds when dealing with complicated sewer systems versus traditional hands-on checks.

Choosing the Right Camera Length and Diameter for Pipe Access

Optimal pipe diagnostics require matching camera dimensions to infrastructure:

- Diameter: Probes from 12 mm (for residential drains) to 40 mm (industrial conduits)

-

Length: Adjustable poles extending up to 150 meters for deep sewer lines

Leading manufacturers now offer modular designs that combine 4K resolution with auto-focus LED lighting, ensuring clarity in pipes as small as 20 mm. This prevents misdiagnoses caused by incomplete visual coverage—a critical factor in 32% of failed municipal inspections (2024 Water Infrastructure Report).

Cost vs. Long-Term Savings in Preventive Sewer Line Maintenance

Retractable inspection systems might cost between three and fifteen thousand dollars initially, but they save money in the long run since traditional sewer repairs typically run anywhere from fifty to two hundred fifty dollars per foot when digging is involved. Looking at a city's experience back in 2022 shows something interesting too. When they started doing these camera checks twice a year instead of waiting for problems, emergency service calls dropped nearly four out of five times within just five years. Take Tacoma, Washington as an example. They spotted small issues before they became big ones and saved almost three million bucks on replacing entire pipes according to research published by NASTT last year. While not every utility has jumped on board yet, most American water departments have recognized the value proposition here based on what we're seeing nationwide.

Comparative Benefits of Retractable Inspection Cameras vs. Borescopes

Retractable Inspection Camera vs. Traditional Borescopes in Tight Spaces

The retractable inspection cameras beat the old school rigid borescopes at getting around those tight spots we find in all sorts of industrial machinery and HVAC systems. Standard borescopes just can't handle corners over 90 degrees without major issues. The retractable ones actually compress their diameter by about 60% which lets them squeeze through pipes as small as 25mm even if there are several bends along the way. Some real world testing back in 2023 showed that inspectors saved roughly 35% of their time checking valves with these flexible cameras instead of the semi-rigid alternatives. The main reason? They don't have to take apart so many components during inspections anymore.

Hybrid Solutions: Merging Borescope, Fiberscope, and Video Scope Features

Modern hybrid inspection systems combine the depth resolution of fiberscopes (up to 50,000 pixels), the adjustability of retractable camera poles (extending 1–10 meters), and real-time video streaming capabilities. These systems now integrate:

- Interchangeable 4–9mm camera heads with 120° wide-angle lenses

- Dual-channel lighting (LED and laser grid for depth perception)

- Wireless image transmission meeting IP67 waterproof standards

A 2024 survey of maintenance teams showed hybrid devices reduced equipment downtime by 28% in power plant inspections through faster defect identification and documentation.

Frequently Asked Questions

What are retractable inspection cameras?

Retractable inspection cameras are advanced diagnostic tools used to carry out non-destructive testing in confined spaces. They feature extendable shafts and high-definition imaging to detect defects in hard-to-access areas.

What are the benefits of using retractable inspection cameras?

The benefits include reduced operational downtime by up to 40%, superior imaging for defect identification, and versatility for use in various environments such as HVAC ducts and underwater infrastructure.

How do retractable inspection cameras differ from traditional borescopes?

Unlike traditional borescopes, retractable inspection cameras have flexible and extendable shafts, making them ideal for navigating tight corners and complex pipelines without disassembling equipment.

What role does IoT play in the functionality of retractable inspection cameras?

IoT integration enables these cameras to send 4K video footage to the cloud and offers real-time remote video inspection capabilities, facilitating quicker problem-solving and better collaboration between onsite and offsite engineers.

Are retractable inspection cameras weather-resistant?

Yes, many models feature waterproof and chemical-resistant construction, employing materials like marine-grade aluminum and carbon fiber composites to withstand harsh conditions.

Table of Contents

- How Retractable Inspection Cameras Improve Industrial Diagnostics

- Core Mechanics of the Retractable Inspection Camera Structure

- Material Innovations: Waterproof and Chemical-Resistant Construction

- Stability and Adjustability in Extended Reach Applications

- High-Resolution Imaging for Clear Visual Diagnostics in Tough Conditions

- Key Applications in Plumbing, Sewer Lines, and Confined Space Inspections

- Comparative Benefits of Retractable Inspection Cameras vs. Borescopes

-

Frequently Asked Questions

- What are retractable inspection cameras?

- What are the benefits of using retractable inspection cameras?

- How do retractable inspection cameras differ from traditional borescopes?

- What role does IoT play in the functionality of retractable inspection cameras?

- Are retractable inspection cameras weather-resistant?