Why High-Resolution Matters in Sewer Inspections

Identifying Micro-Fractures & Root Intrusions

High res imaging is really important when looking for those small structural issues in sewer lines, especially things like micro fractures. What might appear as just tiny cracks on the surface can actually cause big problems down the road, eventually weakening the whole sewage system. Using high resolution cameras lets us spot these little cracks before they turn into bigger fractures that would cost a fortune to fix or worse, cause complete system failure. Then there's the problem of roots getting into the pipes. Tree roots are always looking for water sources, so they'll find their way through any small crack or joint in the sewer line, causing blockages and sometimes even collapsing sections of pipe entirely. The high res cameras give technicians a much better view inside the pipes, making it possible to catch root intrusion problems right at the start of inspections. Research shows that most sewer failures happen because these micro fractures and root invasions go unnoticed until it's too late, which is why thorough drain inspections should be standard practice for anyone dealing with underground plumbing systems.

Detecting Corrosion in Aging Pipe Networks

Older sewer systems tend to suffer from corrosion problems that end up costing municipalities a fortune in repairs. When pipes sit exposed to corrosive substances for years on end, they start breaking down and putting the whole network at risk. That's where those fancy high-res inspection cameras come in handy. These cameras give clear pictures of exactly where corrosion is happening inside the pipes, so crews can fix things before it gets worse and saves money on big repairs later. Most engineers will tell anyone who'll listen that many sewer system failures actually happen because nobody noticed the corrosion early enough. Technicians using these cameras spot problem spots much easier, which helps them decide whether to patch up a section or replace it entirely. Getting this kind of tech involved in regular inspections makes all the difference. Instead of waiting until something collapses, cities can catch corrosion early and keep their sewer systems running longer without constant emergency fixes.

Key Features of Modern Sewer Inspection Cameras

4K Imaging & 360° Articulation Capabilities

Modern sewer inspection cameras equipped with 4K imaging have really changed how things work in the field. The footage they capture is so clear compared to older standard definition models that problems in pipes which would otherwise go unnoticed become obvious. We can spot tiny cracks or buildup that could cause bigger issues down the road. Another big plus is the 360 degree articulation feature. This means technicians can get views from all angles without having to move equipment around constantly. No more missing stuff behind bends or corners where trouble tends to hide. Some studies show that when municipalities upgraded to these better cameras, their inspection success rates jumped about 30 percent. Makes sense too since clearer pictures lead to better decisions about what needs fixing.

Laser Measurement Systems for Crack Sizing

Putting laser measurement systems into sewer inspection work has proven really helpful, especially when it comes to getting exact sizes of those cracks we find. These systems give super accurate readings which helps engineers come up with better repair plans that save money down the road. When we know exactly how big a crack is, we can fix it just right without going overboard or leaving things half done. Take one city's big sewer system as an example. They used laser tech to spot problems early on and made fixes before things got worse, which saved them tons of time and cash in the end. Being able to measure issues properly means making smarter choices about where to spend limited resources, something every municipality wants to do.

ATEX-Certified Models for Hazardous Environments

When working on sewer line inspections in dangerous areas, getting proper ATEX certification matters a lot. What this means practically is that all the gear being used must be built to prevent explosions in places where flammable gases might be present. That's not just good practice but essential for keeping workers safe. Most ATEX certified cameras for sewers have things like reinforced outer shells and special internal components that stop sparks from causing problems during tough inspection jobs. Regulations across the industry basically require this kind of equipment for any work in these risky conditions. Take OSHA standards as an example they specifically call out the need for explosion protected equipment during inspections. So whether it's methane buildup or other volatile substances, having those ATEX certified tools on hand isn't optional it's how we stay compliant while doing the job right.

Critical Applications Across Infrastructure

Municipal Sewer Line Inspection Protocols

Cities typically stick to set procedures when checking their sewers, which helps keep those vital underground systems running smoothly. These checks matter because they catch problems early on before small cracks turn into big disasters, protecting both residents' health and saving taxpayer money in the long run. When municipalities skip these regular looks around, things tend to go south pretty quickly. We've seen plenty of situations where ignored maintenance resulted in massive backups that flooded streets and contaminated local waterways. Groups such as the Water Environment Federation constantly remind communities about the value of sticking to inspection schedules so everything keeps working properly without unexpected breakdowns. Most towns already have established practices for these checks, and following them makes all the difference between smooth operations and expensive fixes down the road.

Industrial Drain Inspection Requirements

Industrial drain inspections come with their own set of rules that are quite different from what we see in regular city sewer systems. This is mainly because factories deal with all sorts of complicated substances and chemicals that can really mess things up if they get into the wrong places. Regulations these days demand pretty high tech equipment for proper checks. When companies fail to follow these rules, they don't just get slapped with big fines either. Public health gets put at risk along with our environment. Take chemical plants or food processing facilities for instance. These operations need regular look-overs to keep track of what's going down the drain. Most inspectors now rely on camera systems pushed through pipes or flexible borescopes to actually see inside those dark, dirty tunnels. Getting clear visuals helps them spot problems early before anything serious happens, which ultimately keeps everyone safer and avoids costly cleanups later on.

Pre-Purchase Sewer Pipe Inspection Essentials

Getting sewer pipes checked out before buying a house can really help spot problems that might cost a fortune later on. Anyone thinking about purchasing property would do well to get those inspection reports done right away, looking closely at things like how solid the pipes are, if there's anything blocking them, any leaks happening, or roots growing into the system. The numbers don't lie here folks - people who check their sewers beforehand often end up saving themselves serious cash down the road. We're talking about thousands saved sometimes just by knowing what's wrong upfront. What happens during these inspections? Well, someone will snake through the entire sewer line, taking a good look at its overall condition and pointing out spots where immediate work might be needed. Spending money now on proper inspections actually makes sense when buying property because it gives buyers all the info they need to make smart choices and avoid getting hit with unexpected bills after closing day.

Technological Advancements Driving Precision

AI-Powered Defect Recognition Software

The way we inspect sewers is changing fast thanks to artificial intelligence that automatically spots problems, making things both faster and more accurate. Industries really depend on regular checks of their sewer lines to keep operations running smoothly, especially places like water treatment plants and big factories. Take AI algorithms for example they can go through mountains of data to find issues that might otherwise be missed during manual inspections. People who know what they're talking about, including folks at Astute Analytica, point out that bringing AI into the mix cuts down on how long inspections take while also catching more problems than traditional methods. What's interesting is how these technological improvements aren't just saving time money but actually preventing bigger issues down the road when small defects get fixed before they become major headaches.

Cloud-Based Reporting for Compliance Tracking

Bringing cloud tech into compliance tracking after sewer inspections brings several advantages worth noting. Departments no longer struggle with storing and sharing all that paperwork because everything gets organized in one place online. When inspectors finish checking drains, their reports go straight to whoever needs them next, which means problems get fixed faster instead of sitting on someone's desk. The construction industry has seen compliance rates jump significantly since adopting these systems. Workers can pull up past inspection records instantly during site visits, so they spot potential issues before they become big headaches. For municipal wastewater management teams specifically, cloud platforms make it easy to monitor hundreds of sewer lines at once. This keeps communities compliant with environmental standards while saving money on unnecessary repeat inspections down the road.

GIS Integration for Infrastructure Mapping

GIS technology has become really important for handling all sorts of infrastructure information, particularly when it comes to checking out sewer pipes. What makes GIS so useful is its ability to analyze spatial data, which helps make inspections much more efficient by creating detailed maps of entire sewer systems. When these systems are integrated properly, they let workers find exactly where problems exist in the network, making repairs and maintenance work way better than before. Cities across the country that started using GIS for their infrastructure work saw real improvements in how they manage sewage networks. Take Chicago as one example where the system helped inspectors cover more ground during routine checks. The real value here isn't just about saving time though. Having good GIS tools means communities can plan ahead for future needs while keeping those complicated sewer systems running smoothly without constant breakdowns.

By adopting these technological advancements, industries can achieve higher precision in sewer inspections, ensuring efficient operations and compliance while minimizing downtime and costly repairs. These technologies represent pivotal steps forward in modernizing how we monitor and maintain essential infrastructure.

Choosing Sewer Inspection Services Near You

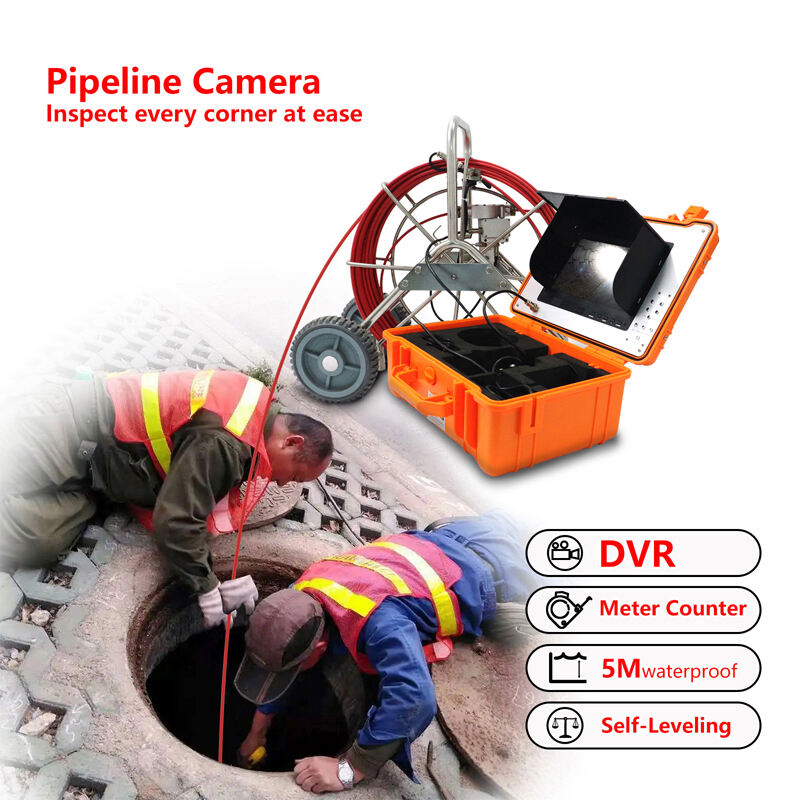

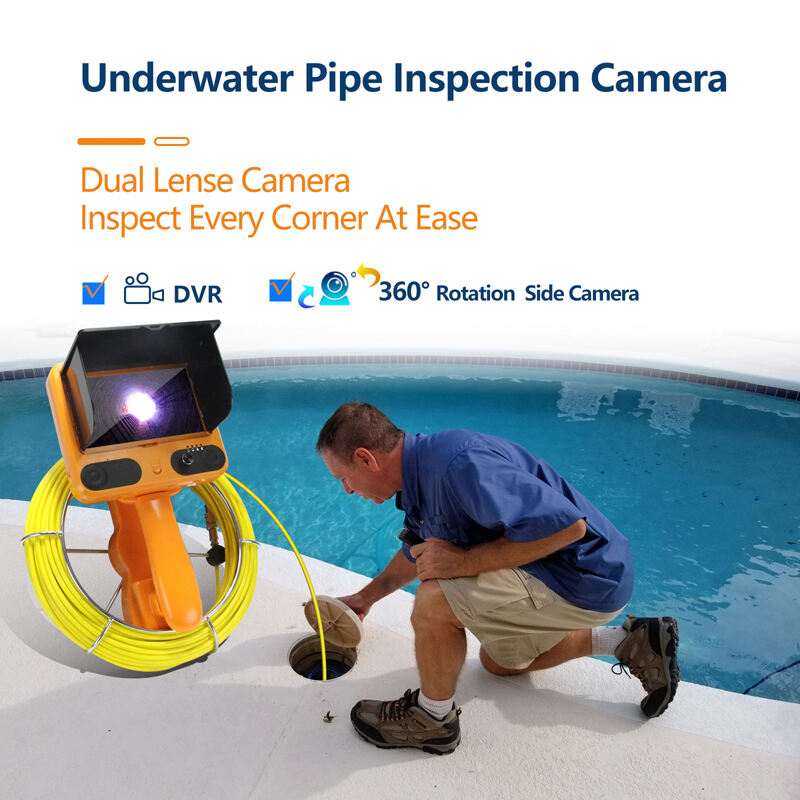

Evaluating Camera System Specifications

Picking the right sewer inspection service means looking closely at what kind of camera equipment they actually use for getting those diagnostic results. Resolution matters a lot because it tells us how clear those pictures will be inside those dark pipes. Then there's articulation too important since good cameras need to bend and twist their way through all sorts of pipe configurations without getting stuck. The better models come with crystal clear imaging capabilities plus flexible movement options so inspectors don't miss anything during their checkups. Spending money upfront on quality gear pays off later when major repair bills get avoided. Don't forget about basics either water resistance ratings, how tough the casing is against rough handling, and just how long that inspection cable runs before needing replacement these factors really determine whether an inspection turns out useful or wastes everyone's time.

Understanding Sewage Line Inspection Reports

Looking at sewage line inspection reports is pretty much essential when trying to figure out how healthy our sewer systems really are. When we know what to check for in these reports, it gives us some real good clues about what might be going wrong down there and what kind of maintenance work needs doing soon. Most reports will show things like the overall condition of pipes, where there are blockages happening, any cracks or breaks in the lines, plus those pesky roots that keep growing into the system causing all sorts of problems. Getting this information straight helps decide which repairs need attention first before they turn into bigger headaches later on. And let's face it nobody wants to pay fines after an inspection either. So taking time to go through these reports properly means better decisions get made about fixing issues before they become expensive disasters waiting to happen.

Cost vs. Value in Preventative Maintenance

Getting the right balance between what inspection services cost at first and what they save over time matters a lot when planning budgets. Sure, paying for these inspections upfront can look expensive, but most folks find that regular checks actually pay off big time by stopping major repair bills down the road. Take some real world examples we've seen recently, towns that invested in checking their sewers regularly ended up avoiding millions worth of damage to roads and buildings because problems were caught early. The pros who work on this stuff all the time stress how important it is to make sewer inspections part of the regular budget rather than an afterthought. When municipalities treat these checks as essential rather than optional, their systems tend to last longer and perform better, which means less money spent fixing things later on.

Table of Contents

-

Why High-Resolution Matters in Sewer Inspections

- Identifying Micro-Fractures & Root Intrusions

- Detecting Corrosion in Aging Pipe Networks

- Key Features of Modern Sewer Inspection Cameras

- 4K Imaging & 360° Articulation Capabilities

- Laser Measurement Systems for Crack Sizing

- ATEX-Certified Models for Hazardous Environments

- Critical Applications Across Infrastructure

- Municipal Sewer Line Inspection Protocols

- Industrial Drain Inspection Requirements

- Pre-Purchase Sewer Pipe Inspection Essentials

- Technological Advancements Driving Precision

- AI-Powered Defect Recognition Software

- Cloud-Based Reporting for Compliance Tracking

- GIS Integration for Infrastructure Mapping

- Choosing Sewer Inspection Services Near You

- Evaluating Camera System Specifications

- Understanding Sewage Line Inspection Reports

- Cost vs. Value in Preventative Maintenance